Void fillers are essential for strategic load securement systems — they help contain and brace products during transit to avoid excess movement. Often composed of durable and customizable corrugated materials, these void panel solutions provide reliable support and can be tailored to your precise needs. Their versatility and effectiveness make them an unmatched choice for protecting many products, from food and beverage to industrial and home improvement products and much more.

Without void fillers, your products may be at risk of damage and could cause an unsafe loading and unloading experience. Product damage is expensive and time-consuming to resolve, and maintaining a safe workplace is essential to meet necessary safety standards and set your team up for success. With void panel solutions, you can count on your product arriving intact.

There are many types of void filler options available, from honeycomb panels to collapsible varieties that can be stored away. Do you know how to pick the right void filler for your application? Follow this streamlined guide to choose the best solution for your needs and leverage it to support your products and bottom line.

Common Void Panel Options

At Sunrise, we offer a wide array of void panel solutions that can be tailored to best address the needs of our customers based on their product, shipping method, and overall application needs.

Collapsible Void Filler

Collapsible void fillers can be stored flat, saving valuable space and reducing shipping costs. It’s an even more flexible option than its standard counterparts and offers users the chance to enjoy added flexibility within a high-quality and versatile void panel solution.

Some quality collapsible void fillers from Sunrise include:

- DIAMOND-CORR® – This original collapsible void filler expands to best fit between loads and prevents load shift.

- DIAMOND-CORR II® – This filler expands and is created with larger cells to offer a more cost-effective lateral void filler.

- SADDLE-PAK® – This unique void panel was designed for singled-out units and consists of two filler sections that join to the sides of your products with a flat layer atop it. It better distributes weight and fills voids on each side of the unit.

- MATCH BOOK® – This collapsible void panel is corrugated backed and its self-supporting nature allows it to be free-standing as it prevents cross wide load shifting.

- LEDGE-PAK® – This solution is designed to prevent lengthwise load shift due to pallet underhand. Its patented design offers enhanced security and peace of mind.

Non-Collapsible Void Filler

Non-collapsible void filler is less flexible than its collapsible counterpart, but can also offer even greater rigidity and support to better brace your products and keep them in proper alignment through shipping.

Some non-collapsible options include:

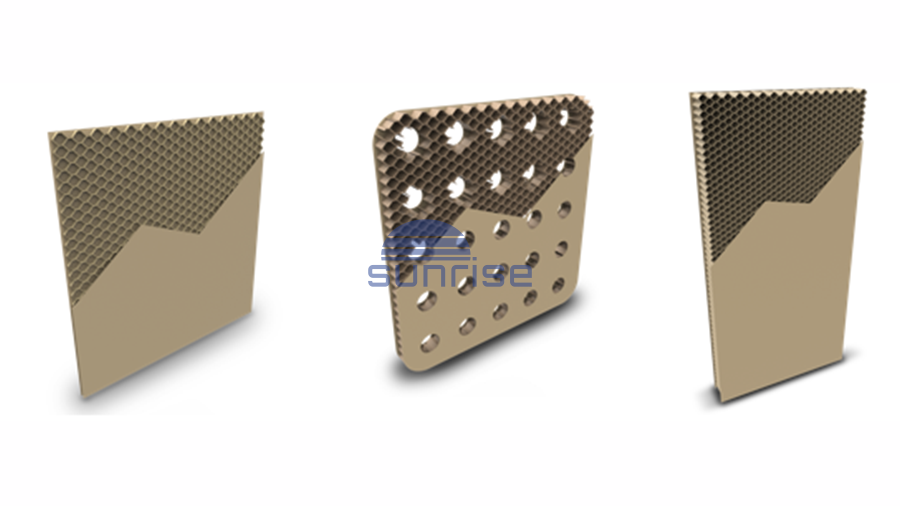

- SUNRISE SMALL CELL – This unique small cell honeycomb void filler is lightweight yet dense, offering a compression strength of 10-69 PSI.

- DIAMOND-PAK® – This larger cell honeycomb bulkhead void filler may be customized from standard square or rectangle panels to rounded shapes used as risers. Also available with blocks, contoured edges, wedges, and more. WOOD-PAK® – This filler combines corrugated materials and lumber, serving as a durable option to prevent end-to-end toppling.

- RAIL-PAK® – This versatile void filler system encompasses three product types that deliver highly specialized support to various applications from BIN-PAK™ and DRUM-PAK™ focused on food and industrial shipments to LUMBER-PAK™ which was intended for open top forestry shipments.

4 Steps to Finding the Best Void Filler

1. Collapsible vs Non-Collapsible?

To narrow down the list of void panel options and find the best fit, evaluate whether you want to use collapsible or non-collapsible varieties. Collapsible varieties oftentimes ship flat, helping to save freight costs and reduce warehouse space needed. Non-collapsible options provide enhanced rigidity and protection and can be produced in unique shapes like wedges and rounded styles to deliver more tailored support.

2. Evaluate Your Product

Some products benefit from the specialized support void filler can offer. SADDLE-PAK® can expand over single pallet units to offer enhanced protection on multiple sides. Need a solution to prevent lengthwise load shift? Turn to the patented LEDGE-PAK®. If you require more tailored support, the DIAMOND-PAK® may be customized from flat honeycomb panels to contoured wedges, allowing you to better secure your products.

3. Evaluate Your Modality

It’s important to understand the way your modality will influence the void fillers that work best. LUMBER-PAK™ was designed for open car shipments, while BIN-PAK™ was designed for bin shipments in boxcars. Choosing the right solution for your shipping method will ensure it best matches up with the needs and challenges your products may have within these unique environments.

4. Talk to the Experts

Before you invest in void filler solutions, talk to the packaging and freight protection experts to ensure you’re using the right products to protect your bottom line. With a seasoned team on your side, you can count on more support in finding the best void panel options for your products and budget.

At Sunrise, we help our customers develop custom load securement solutions, and we’re here to evaluate the best honeycomb void filler options for your needs. Our industry partnerships with the Association of American Railroads and others empower us to deliver expert support designed to stay on the leading edge of freight protection so you can trust that our solutions meet every safety standard and recommendation. Our diverse capabilities and commitment to customized support help us offer the best void panels to our customers based on their unique needs.

Contact Sunrise Today for Superior Void Panel Support

Sunrise is proud to offer tailored solutions for businesses across all industries seeking to level up their product protection through transit. We understand the many essential steps to a superior load securement system and we offer a wide array of products to help you curate the best freight protection for your needs. We’re a total project partner here to serve you from the beginning to the end and even offer on-site training for your teams.

With five US locations, we’re prepared to serve businesses of all industries across the nation. Trust our sustainable void filler and commitment to the highest-quality customer support to help you achieve better results today. When you’re ready to level up your product protection, contact us for valuable void panel support.